Importance of Riving Knives

I have visited a few sheds lately and have been quite surprised at how many of them have removed the riving knife from their saw benches, I consider this to be seriously bad practice!

Riving knives are fitted to machines by the manufacturer for one main reason, to keep the user safe (or at least safer?) from kickback, the secondary reason is to prevent the timber from binding on the blade and overloading the saw this also makes it easier for the piece of timber to pass beyond the blade with less effort being required by the operator.

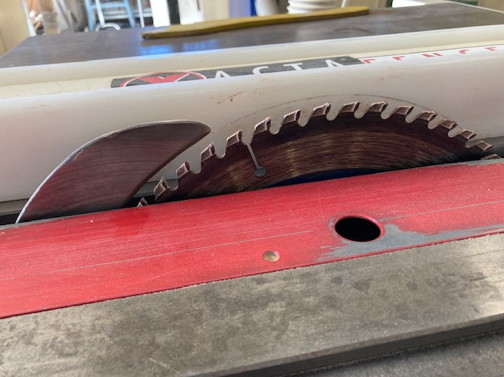

A riving knife is a piece of steel fitted to the arbour of the saw so that it moves with the adjustments made to the blade height and is positioned immediately behind the blade. It should be slightly thicker than the body of the blade and slightly thinner than the overall width of the teeth thereby riding within the cut (kerf) thus preventing the closing of the cut onto the body of the blade. It is possible that you may need to have different knives for some blades although this is generally never required. Given that the knife moves with the blade a low profile knife should always sit slightly lower than the top of the blade regardless of the blade height. This eliminates the need to remove the blade for rebating or tenoning timber, if you never remove it then you never forget, or simply ignore, putting it back on! These Riving Knives will be in the shape of a crescent moon and therefore quite narrow at the top resulting in only a small portion of it being within the kerf.

Some riving knives are of a higher profile and have a guard fitted to them, such as on my personal saw. This is also quite broad at the top. These arrangements are good due to the fact that there is no additional framework to hold the guard but if I want to cut a rebate then the guard must be removed and the knife adjusted to be lower than the top of the blade. Whilst I can cut a rebate with it, due to its width and therefore having quite a lot of knife within the kerf I find that removing it is better. Of course by doing this I have also exponentially increased the risk factor, particularly as I often don’t put it back on for a while despite knowing better!! Yeah well, as the old saying goes, do as I say not as I do!!

Some saws, generally older models, have what is called a splitter fitted to them, this serves the same purpose as a riving knife but is entirely separate from the blade adjustment mechanism and therefore remains stationary regardless of blade height adjustments, as the blade is lowered the distance from the blade to the splitter also increases. I would say that if your saw has a splitter then it is time for an upgrade.

There are a number of reasons why kickback is caused, some of it set up related, some of it timber related and also the old ‘operator error’. The first one is that the fence is not dead parallel with the blade, not only will this force the timber onto the blade if the back is too close, if it is further away it will cause the timber to move off the fence as it travels and the piece will highly likely end up being out of parallel in its cut width. Precise adjustment is required between the two.

The timber issue is the big one! It is that as a piece of timber is cut tension is released within it causing it to close together and bind upon the rear of the blade, this will cause the blade to want to cut upwards, as this is the direction of the rotation at the rear and the piece will either chatter, or bounce, and if it can become free it will be lifted by the blade and ejected straight back at the operator. The rate of acceleration will be relative to the speed of the blade at its outer edge, this will be something in the order of 226klm/hour (4000rpm and a 300mm blade), so you can imagine that the piece of timber will be travelling rather quickly in a very short space of time. A riving knife, or splitter, will prevent this. Another really dangerous effect of the timber becoming unstable as it passes beyond the blade is that the operator will often put their hand upon the piece behind the blade to prevent it lifting, never, ever, do this! If the piece decides to kickback your hand will travel with it and guess what, no fingers in an instant! or at least very mangled and extremely painful ones. I do know a member of a shed who has suffered this experience, he has assured me that it was quite unpleasant.

The last reason that it may occur is that the operator is not feeding the piece into the saw with it being properly against the fence, thereby causing the piece for be forced against the blade, this will result in an awkward and potentially dangerous process and a poorly cut piece. This little issue also relates to the person who may be assisting by taking control of the piece after it passes the blade. This is called tailing out and is actually not just stopping the piece from falling on the floor as most people think but it is in fact taking control of the process so that the person feeding the piece into the saw can remove themselves and therefore their hands from it. The person tailing out assumes responsibility for the passage of the timber at probably a little over the halfway point (depending upon the length of the piece of course) and must ensure that it remains against the fence, they also take control of the feed rate, or at least that is how it is supposed to be?

I have noticed that the person feeding the timber into the saw invariably keeps trying to control it right up to the finish of the cut, and therefore their hands encroach far too close, even with a push stick. This should not be necessary if the other person knows what is required of them, knows how to do it and is allowed to do it. Of course the person doing the tailing out should not have their hands anywhere near the blade either, I advise never nearer than the edge of the saw table.

Whilst on the subject of Kickback please be aware that it can also happen from other machines, router tables and spindle moulders (a very dangerous machine indeed!) being the two most common but it can also happen with just about any tool that is spinning, such as a jointer/planer, so be aware and be careful! The kickback can not only launch a piece of timber back at the user but if they have been foolish enough to put their hand behind the blade then that hand will be carried straight to the cutting edge and severed or severely lacerated in an instant. Remember that saws have a tooth speed of some 226 klm/hr, spindle moulders are faster than that so you are not going to avoid being injured.

Please be careful in using all the machines in a woodworking workshop, they can all injure the user and whilst being careful is one thing being scared is another, this can actually be dangerous in itself as the user is reluctant to control the work adequately and will cause the accident to happen. If you are not confident then don’t do it and if you are too confident don’t do it either!!

Happy woodworking – David Gray

This article first appeared in the Spring 2021 edition of the Tasmanian Men’s Shed Association SHED NEWS magazine. Reprinted with the kind permission of the TMSA and the author, David Gray.